Specific guidance on protection against impact with glazing is contained in K4 of – Building Regulations Approved Document K.

To meet these requirements the architect needs to ensure that all critical locations are glazed in such a way that;

Prior to legislation on minimum standards for glazing in low level areas; children were at particular risk of injury. Accidental impact could result in a child being showered with shards of falling glass and there are many horror stories of children inadvertently kart wheeling through patio doors.

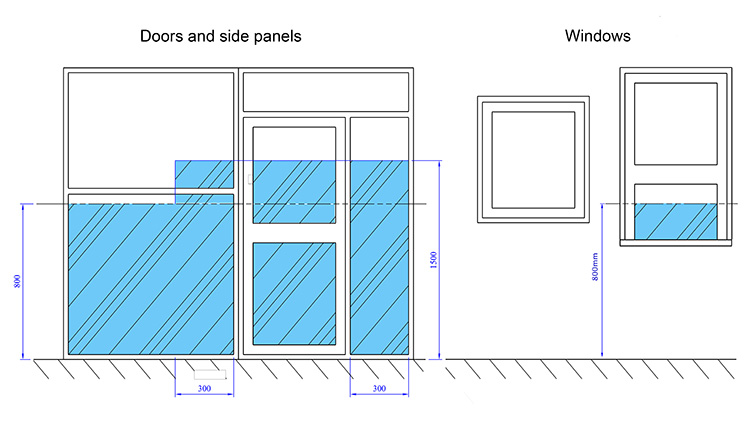

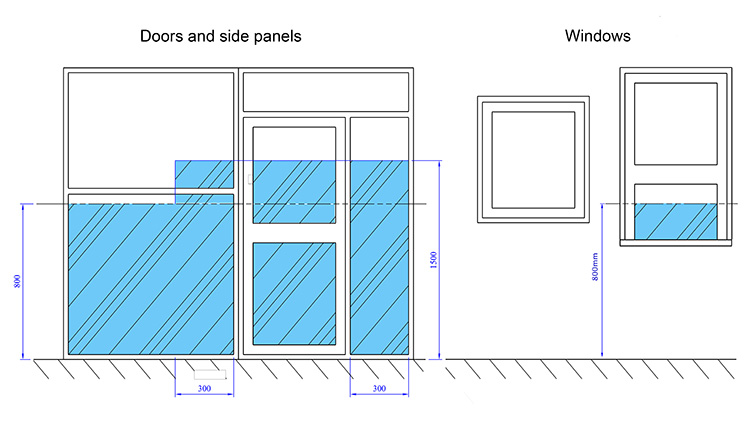

Document K divides the ‘Critical glazing locations’ into two distinct areas.

The highest risk area – Glazing in a door and in a door side panel with a width greater than 900mm (for this area the minimum glazing specification is Class B of BS 6206.)

Generic risk area – The remainder of any glazing at low level (for this area the minimum glazing specification is Class C of BS 6206).

Selectaglaze uses a range of glazing depending on the benefits required by its clients and the particulars of a given project. However; in the aforementioned areas, our units are only ever glazed with glass that complies with Class B as a minimum.

Safety glass must be indelibly marked with the following:

Prior to legislation on minimum standards for glazing in low level areas; children were at particular risk of injury. Accidental impact could result in a child being showered with shards of falling glass and there are many horror stories of children inadvertently kart wheeling through patio doors.

Document K divides the ‘Critical glazing locations’ into two distinct areas.

The highest risk area – Glazing in a door and in a door side panel with a width greater than 900mm (for this area the minimum glazing specification is Class B of BS 6206.)

Generic risk area – The remainder of any glazing at low level (for this area the minimum glazing specification is Class C of BS 6206).

Selectaglaze uses a range of glazing depending on the benefits required by its clients and the particulars of a given project. However; in the aforementioned areas, our units are only ever glazed with glass that complies with Class B as a minimum.

Safety glass must be indelibly marked with the following:

- measures are taken to limit the risk of cutting and piercing injuries by the specification of glazing which is reasonably safe. This is defined as, glazing which if broken, will break in such a way that the particles do not pose a hazard

- the glazing installed is strong enough to ensure the risk of breakage is low

- measures are taken to ensure that there is a barrier placed in front of the glazing

Example of critical glazing location in internal walls

Prior to legislation on minimum standards for glazing in low level areas; children were at particular risk of injury. Accidental impact could result in a child being showered with shards of falling glass and there are many horror stories of children inadvertently kart wheeling through patio doors.

Document K divides the ‘Critical glazing locations’ into two distinct areas.

The highest risk area – Glazing in a door and in a door side panel with a width greater than 900mm (for this area the minimum glazing specification is Class B of BS 6206.)

Generic risk area – The remainder of any glazing at low level (for this area the minimum glazing specification is Class C of BS 6206).

Selectaglaze uses a range of glazing depending on the benefits required by its clients and the particulars of a given project. However; in the aforementioned areas, our units are only ever glazed with glass that complies with Class B as a minimum.

Safety glass must be indelibly marked with the following:

Prior to legislation on minimum standards for glazing in low level areas; children were at particular risk of injury. Accidental impact could result in a child being showered with shards of falling glass and there are many horror stories of children inadvertently kart wheeling through patio doors.

Document K divides the ‘Critical glazing locations’ into two distinct areas.

The highest risk area – Glazing in a door and in a door side panel with a width greater than 900mm (for this area the minimum glazing specification is Class B of BS 6206.)

Generic risk area – The remainder of any glazing at low level (for this area the minimum glazing specification is Class C of BS 6206).

Selectaglaze uses a range of glazing depending on the benefits required by its clients and the particulars of a given project. However; in the aforementioned areas, our units are only ever glazed with glass that complies with Class B as a minimum.

Safety glass must be indelibly marked with the following:

- name and trademark of manufacturer, merchant or installer

- the identifier of the product standard the safety glass conforms to; e.g. BE EN 12150; BS EN 14179; BS EN 14449

- the classification according to BS EN 1260

- Date

- Category

- Secondary Glazing in Practice