Some specifications have so many elements to consider that they can become a minefield, especially when working in Listed buildings.

One element on a particular project, which proved to be more complex than normal, was treating full height stained glass windows with an arched head, which were cut in-two by a mezzanine level. In addition, the building is Grade II* Listed, so the treatment had to be discreet and sympathetic.

The secondary glazing was being specified to provide acoustic insulation to achieve a desired reduction of >46dB as set out in the planning permission documents. Not only was noise reduction required, but it also had to act as a barrier, to comply with Part K of the Building Regulations, where voids were created at the meeting of the window reveals and the mezzanine level.

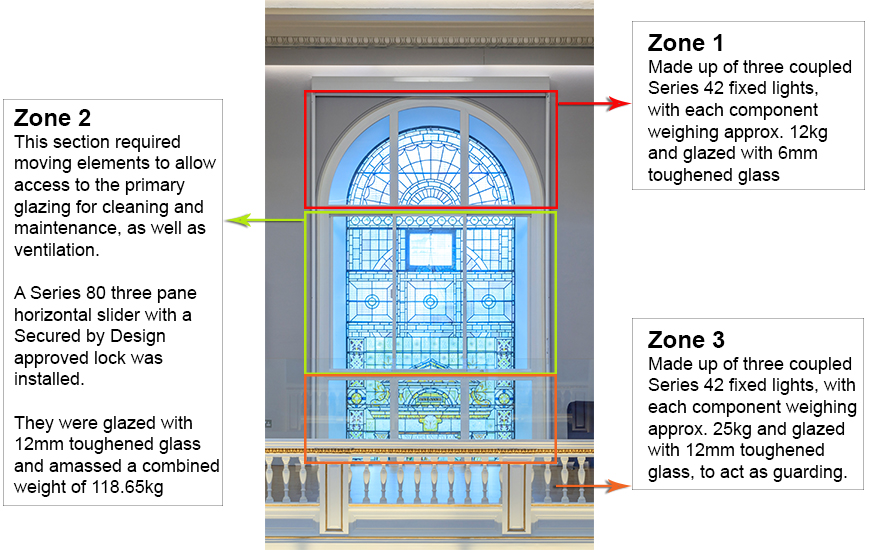

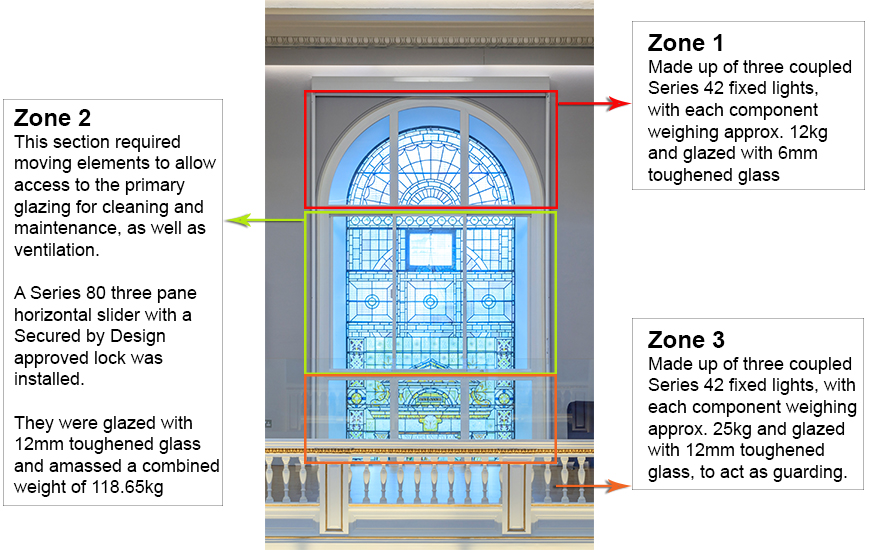

Due to the size of the opening, the secondary glazing on the upper level had to be split into three parts, all of which carefully followed the original sightlines. This was due to the reveal being too large for a single window opening, plus the sheer weight of a unit that size would have compromised safety of operation. The overall dimensions were 3855mm (h) x 2560mm (w) and it weighed approximately 230kg.

The building in question was being converted from a deconsecrated church into a sports and local community centre. With physical activities being carried out on both floors for all ages, the void between the mezzanine and primary windows posed a safety issue hence the need to comply with Part K – Guarding.

Initially, one large panel for zone 3 was specified by the architect; however the safety of this had to be verified with the glass manufacturer. With the potential for the glass to be broken or shattered from a child running into it, or a piece of sports equipment banging against it, a single pane was deemed unsuitable. To comply with deflection loads for 12mm toughened glass, the maximum panel size recommended to withstand a 1.5kN concentrated load is 1000mm (w) x 1100mm (h). Therefore, to enable a sympathetic and discreet treatment, the panel was split into 3 following the main lead lines of the stained glass. This was then carried through to the full height of the window to create a balanced look as well as making all the panes manageable in terms of manual handling for fixing.

The building in question was being converted from a deconsecrated church into a sports and local community centre. With physical activities being carried out on both floors for all ages, the void between the mezzanine and primary windows posed a safety issue hence the need to comply with Part K – Guarding.

Initially, one large panel for zone 3 was specified by the architect; however the safety of this had to be verified with the glass manufacturer. With the potential for the glass to be broken or shattered from a child running into it, or a piece of sports equipment banging against it, a single pane was deemed unsuitable. To comply with deflection loads for 12mm toughened glass, the maximum panel size recommended to withstand a 1.5kN concentrated load is 1000mm (w) x 1100mm (h). Therefore, to enable a sympathetic and discreet treatment, the panel was split into 3 following the main lead lines of the stained glass. This was then carried through to the full height of the window to create a balanced look as well as making all the panes manageable in terms of manual handling for fixing.

The secondary glazing was set 200mm glass to glass in the cavity to not only give a look of consistency throughout the building, but also to provide the air gap to reduce resonance of sound which in turn lessens the ingress/egress of noise. As the primary windows were so old; very thin glass and in areas cracked or with small holes; acoustic laminate glass was also used to help reach the desired dB levels.

What can ordinarily appear to be a simple product to specify; secondary glazing can in fact be incredibly complex, depending on the requirements it has to meet. This proved to be a challenging specification for the architect and Technical Advisor, but one which is very successful and performing very well.

The secondary glazing was set 200mm glass to glass in the cavity to not only give a look of consistency throughout the building, but also to provide the air gap to reduce resonance of sound which in turn lessens the ingress/egress of noise. As the primary windows were so old; very thin glass and in areas cracked or with small holes; acoustic laminate glass was also used to help reach the desired dB levels.

What can ordinarily appear to be a simple product to specify; secondary glazing can in fact be incredibly complex, depending on the requirements it has to meet. This proved to be a challenging specification for the architect and Technical Advisor, but one which is very successful and performing very well.

The building in question was being converted from a deconsecrated church into a sports and local community centre. With physical activities being carried out on both floors for all ages, the void between the mezzanine and primary windows posed a safety issue hence the need to comply with Part K – Guarding.

Initially, one large panel for zone 3 was specified by the architect; however the safety of this had to be verified with the glass manufacturer. With the potential for the glass to be broken or shattered from a child running into it, or a piece of sports equipment banging against it, a single pane was deemed unsuitable. To comply with deflection loads for 12mm toughened glass, the maximum panel size recommended to withstand a 1.5kN concentrated load is 1000mm (w) x 1100mm (h). Therefore, to enable a sympathetic and discreet treatment, the panel was split into 3 following the main lead lines of the stained glass. This was then carried through to the full height of the window to create a balanced look as well as making all the panes manageable in terms of manual handling for fixing.

The building in question was being converted from a deconsecrated church into a sports and local community centre. With physical activities being carried out on both floors for all ages, the void between the mezzanine and primary windows posed a safety issue hence the need to comply with Part K – Guarding.

Initially, one large panel for zone 3 was specified by the architect; however the safety of this had to be verified with the glass manufacturer. With the potential for the glass to be broken or shattered from a child running into it, or a piece of sports equipment banging against it, a single pane was deemed unsuitable. To comply with deflection loads for 12mm toughened glass, the maximum panel size recommended to withstand a 1.5kN concentrated load is 1000mm (w) x 1100mm (h). Therefore, to enable a sympathetic and discreet treatment, the panel was split into 3 following the main lead lines of the stained glass. This was then carried through to the full height of the window to create a balanced look as well as making all the panes manageable in terms of manual handling for fixing.

The secondary glazing was set 200mm glass to glass in the cavity to not only give a look of consistency throughout the building, but also to provide the air gap to reduce resonance of sound which in turn lessens the ingress/egress of noise. As the primary windows were so old; very thin glass and in areas cracked or with small holes; acoustic laminate glass was also used to help reach the desired dB levels.

What can ordinarily appear to be a simple product to specify; secondary glazing can in fact be incredibly complex, depending on the requirements it has to meet. This proved to be a challenging specification for the architect and Technical Advisor, but one which is very successful and performing very well.

The secondary glazing was set 200mm glass to glass in the cavity to not only give a look of consistency throughout the building, but also to provide the air gap to reduce resonance of sound which in turn lessens the ingress/egress of noise. As the primary windows were so old; very thin glass and in areas cracked or with small holes; acoustic laminate glass was also used to help reach the desired dB levels.

What can ordinarily appear to be a simple product to specify; secondary glazing can in fact be incredibly complex, depending on the requirements it has to meet. This proved to be a challenging specification for the architect and Technical Advisor, but one which is very successful and performing very well.- Date

- Category

- Secondary Glazing in Practice