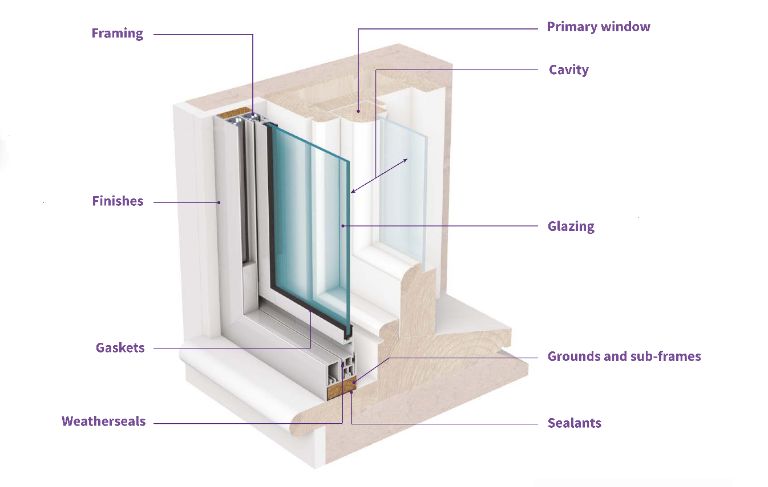

Secondary glazing is a fully independent window system retrofitted on the room side of a primary window.

Secondary glazing is used to enhance the thermal, acoustic and security performance of existing windows. As a reversible adaptation it is generally acceptable for Listed buildings. Effective secondary glazing relies on good seals to maximise the benefits, so each window opening is measured to close tolerance and bespoke frames and timber grounds produced to achieve the closest fit. Glass is carefully selected to meet specific thermal, acoustic or security requirements. Frames are designed to blend in with the existing primary window and to complement the interior aesthetic.The anatomy of Selectaglaze secondary glazing

The standard colour is HIPCA white semi-gloss.

Anodised in natural Silver, Analok Bronze or Black, and a limited range of other colours.

Both paint and anodized finishes are very durable with long life expectancy and minimal maintenance.

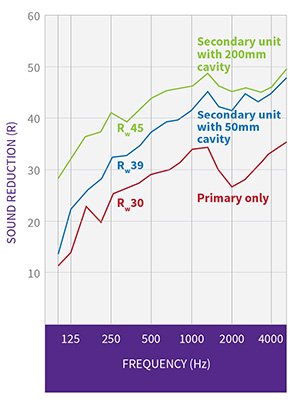

Hinging units are fitted with high performance Q-Lon seals (in white or black). This material has excellent memory and will retain its original shape for years, maintaining optimum sealing and acoustic performance.

Glass thickness varies from 4mm 28mm depending on the product and application.

Other glazing applications include:

Enhanced Thermal

- Low emissivity glass (hardcoat)

- Sealed glass unit (various specifications)

- Acoustic laminates

- Toughened

- Laminated

- Body tinted

- Patterned

- Opaque laminate

- Screen printed or etched

- Switchable glass

- Sealed unit with integral blind

- Anti-reflective glass

- Low iron glass

- Anti-bandit laminates

- Polycarbonate sheet

- Glass/polycarbonate composites

Secondary glazing to suit any design, shape or style of window

Whether the primary window is square or not, there will be something in the standard products range or the specialist shaped and curved treatments, that would suit the opening, match the sightlines and provide a discreet treatment.Product sustainability – recycling and waste

Both main materials are carefully managed and extensively recycled.- Aluminium

Optimized cutting programmes reduce usage, and all cutting waste is recycled. An estimated 90% of aluminium used in buildings is recycled at ‘end of life’ - Glass

Optimized cutting programmes minimise waste. Broken glass (cullet) is recycled in a number of ways, some being turned into new glass and some into alternative materials such as road surfacing