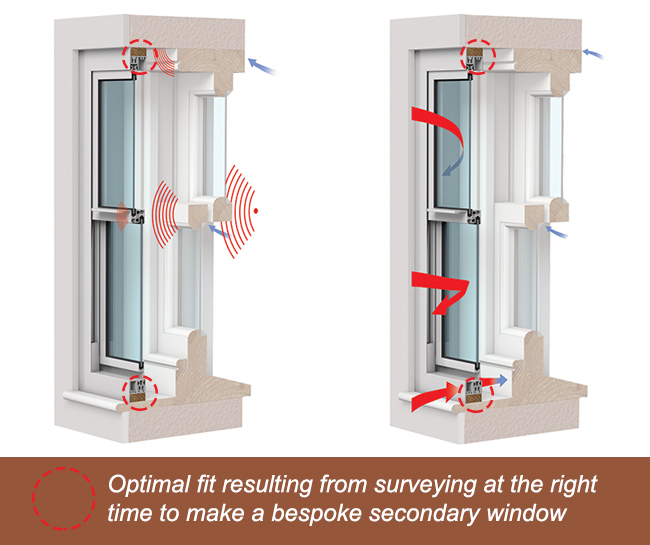

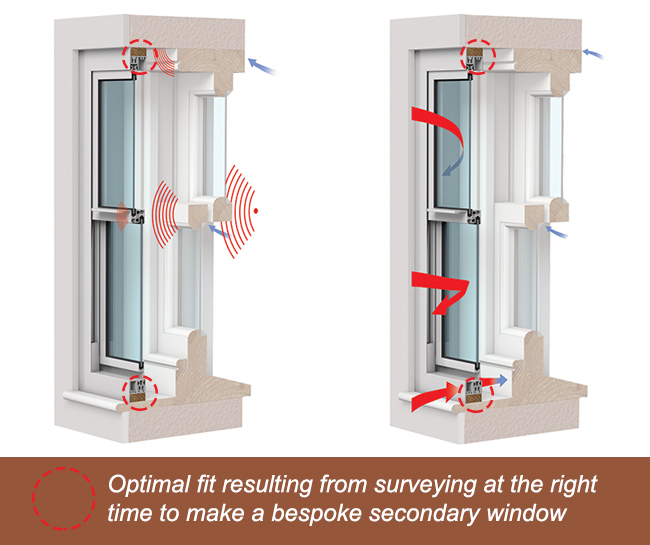

Selectaglaze secondary glazing is proprietary, which when delivered to site is a bespoke complete window with its timber grounds constructed for a specific opening. We manufacture our units to fit within very fine tolerances: 3-5mm each side of the unit, rather than make a unit fit using lots of packers and adding surrounds to hide unsightly gaps.

High performing secondary glazing provides both optimal thermal enhancement and noise reducing qualities to the original window opening. Any large gaps between the frame of the secondary glazing and its surround, will allow draughts to pass through or some noise ingress, which defeats the purpose of its installation.

The best time to survey an opening to get final measurements prior to the manufacture of the units, is when all the works to the primary windows have been completed. This is why we measure twice –first by a technical advisor to obtain details to design a suitable solution and provide an estimate; then at a later stage, by a surveyor, for production. This measurement will be far more comprehensive, checking for level, plumb and true so that the timber grounds can be specified to ensure the best possible interface with the structure.

In many instances where a building is being renovated for change-of-use, plans can evolve throughout the process and change quite dramatically from the initial drafts, having knock-on-effects for us. Such changes can include:

The best time to survey an opening to get final measurements prior to the manufacture of the units, is when all the works to the primary windows have been completed. This is why we measure twice –first by a technical advisor to obtain details to design a suitable solution and provide an estimate; then at a later stage, by a surveyor, for production. This measurement will be far more comprehensive, checking for level, plumb and true so that the timber grounds can be specified to ensure the best possible interface with the structure.

In many instances where a building is being renovated for change-of-use, plans can evolve throughout the process and change quite dramatically from the initial drafts, having knock-on-effects for us. Such changes can include:

The best time to survey an opening to get final measurements prior to the manufacture of the units, is when all the works to the primary windows have been completed. This is why we measure twice –first by a technical advisor to obtain details to design a suitable solution and provide an estimate; then at a later stage, by a surveyor, for production. This measurement will be far more comprehensive, checking for level, plumb and true so that the timber grounds can be specified to ensure the best possible interface with the structure.

In many instances where a building is being renovated for change-of-use, plans can evolve throughout the process and change quite dramatically from the initial drafts, having knock-on-effects for us. Such changes can include:

The best time to survey an opening to get final measurements prior to the manufacture of the units, is when all the works to the primary windows have been completed. This is why we measure twice –first by a technical advisor to obtain details to design a suitable solution and provide an estimate; then at a later stage, by a surveyor, for production. This measurement will be far more comprehensive, checking for level, plumb and true so that the timber grounds can be specified to ensure the best possible interface with the structure.

In many instances where a building is being renovated for change-of-use, plans can evolve throughout the process and change quite dramatically from the initial drafts, having knock-on-effects for us. Such changes can include:

- The introduction of raised floors; which can have implications on the specification of glass used in relation to Building Regulations Part K for protection against impact or falling. Sometimes bulkheads are added or blinds have been placed in front of the primary windows in the opening, which could both have a huge impact on the treatment

- If an original window is refurbished or rebuilt, the works can change the opening sizes or indeed the treatment

- Date

- Category

- Secondary Glazing in Practice